GoodTech MFG Group Limited

Handson Zingying Plastic Metal Ltd

Handson Zingying Plastic Metal Ltd

Views: 676 Author: Site Editor Publish Time: 2025-06-04 Origin: Site

One of the most overlooked — yet critically important — aspects of plastic part design is draft angle. If your part doesn’t have enough draft, it can stick to the mold, cause damage during ejection, or increase tooling wear and cost.

This article explains:

What a draft angle is

Recommended draft angles for different surfaces

What happens if you don’t use enough draft

Tips for designing a better draft

How Goodtech MFG can help you optimize draft early

A draft angle is a slight taper applied to vertical walls of an injection molded part to allow smooth ejection from the mold.

Without draft, parts may drag, warp, or get stuck in the tool during ejection.

It’s measured in degrees, and even a small angle (1°–2°) can make a big difference in production quality.

Surface Type | Recommended Draft Angle |

Smooth, vertical walls | 1.0° – 2.0° |

Textured surfaces | 2.0° – 5.0° or more |

Deep or tall features | 2.0° – 3.0° |

Inside walls (cores) | 1.5° – 3.0° |

Ribs or bosses | 0.5° – 1.0° minimum |

Note: More draft is required for textured or grain-finished surfaces due to friction during release.

Part sticking to the mold

Ejector pins leaving marks or damaging the part

Increased wear on mold surfaces

Slower cycle times and higher risk of defects

Increased tooling costs due to complex ejection mechanisms

Every face that’s parallel to the direction of ejection should have at least 1° of draft — even more if textured.

Design parts with the parting line in mind to ensure draft angles go in the correct direction for ejection.

Most CAD software includes tools to apply draft. Apply it before finalizing geometry to avoid costly changes later.

Some designs may tolerate lower draft, but that depends on material flow, cooling rate, and mold surface finish. Mold flow analysis can help determine minimum draft in critical areas.

Imagine a plastic box with vertical walls:

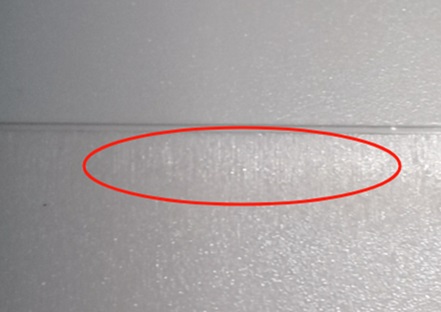

No draft: The walls drag against the mold core during ejection

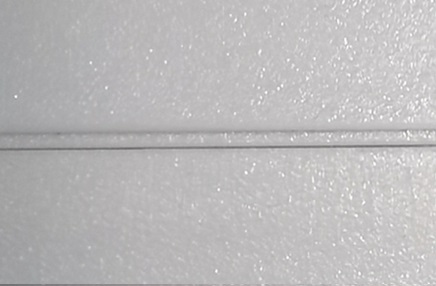

With 2° draft: The part pops out cleanly with no stress

(scratch mark because no molding draft)

(1.5 degrees molding draft)

At Goodtech MFG Group, we support engineers with Design for Manufacturability (DFM) feedback, including draft analysis. Our team helps you:

Detect undercut or zero-draft issues

Suggest ideal draft for your material and finish

Avoid rework and tooling changes