GoodTech MFG Group Limited

Handson Zingying Plastic Metal Ltd

Handson Zingying Plastic Metal Ltd

Views: 693 Author: GoodTech - Mark Li Publish Time: 2025-08-21 Origin: Site

GoodTech MFG

Reading Time: 11 min

Word Count: 2225

Picture Count: 20

Size (words and pictures): 0.95 MB

Material selection is critical in engineering and manufacturing. This guide provides engineer-focused insights into mechanical, thermal, electrical, and chemical properties of 20 commonly used plastics, helping you choose the right material for your application.

HDPE is a semi-crystalline thermoplastic made from polymerized ethylene. Its tightly packed molecular chains provide high strength, chemical resistance, and low moisture absorption.

Morphology: Semi-crystalline with a linear structure, giving high tensile strength and excellent impact resistance at low temperatures.

Key Strengths: High chemical and corrosion resistance, toughness, low density, excellent fatigue resistance, and good dimensional stability.

Applications: Suitable for piping, tanks, containers, geomembranes, and structural components requiring durability in harsh chemical environments.

key characteristics listed below

Property | Value / Range |

Tensile Strength | 20-37 MPa |

Flexural Modulus | 800-1600 MPa |

Elongation | 400-1000 % |

Impact | 20-50 kJ/m2 |

-125 °C | |

Continuous Service Temp | 80 |

Density | 0.94-0.97 g/cm3 |

Dielectric | 20-40 kV/mm |

Chemical Resistance | High |

Applications & Industry Use Cases: Contact GoodTech MFG for custom HDPE components.

LDPE is a thermoplastic polymer with a highly branched molecular structure, providing flexibility and toughness.

Morphology: Semi-crystalline with long-chain branching, resulting in lower density and softer material compared to HDPE.

Key Strengths: High flexibility, chemical resistance, transparency, good impact strength, and easy processability.

Applications: Packaging films, bags, tubing, and flexible containers. Also used in extrusion coating and injection-molded parts requiring elasticity.

key characteristics listed below

Property | Value / Range |

Tensile Strength | 10-20 MPa |

Flexural Modulus | 200-400 MPa |

Elongation | 400-800 % |

Impact | 10-30 kJ/m2 |

Glass Transition Temp | -125 °C |

Continuous Service Temp | 65 |

Density | 0.91-0.93 g/cm3 |

Dielectric | 20-30 kV/mm |

Chemical Resistance | High |

Applications & Industry Use Cases: Contact GoodTech MFG for custom LDPE components.

PP is a semi-crystalline polymer synthesized from propylene monomers. Its molecular structure imparts stiffness, chemical resistance, and fatigue endurance.

Morphology: Semi-crystalline, allowing good dimensional stability and resistance to creep.

Key Strengths: Lightweight, chemical and heat resistance, high fatigue strength, and low moisture absorption.

Applications: Automotive parts, industrial components, consumer goods, and medical devices. Excellent for living hinges, containers, and piping.

key characteristics listed below

Property | Value / Range |

Tensile Strength | 30-40 MPa |

Flexural Modulus | 1300-1800 MPa |

Elongation | 200-600 % |

Impact | 20-50 kJ/m2 |

Glass Transition Temp | -10 °C |

Continuous Service Temp | 100 |

Density | 0.90-0.92 g/cm3 |

Dielectric | 15-30 kV/mm |

Chemical Resistance | High |

Applications & Industry Use Cases: Contact GoodTech MFG for custom PP components.

PS is an amorphous thermoplastic polymer derived from styrene monomers. Its structure provides rigidity and ease of processing.

Morphology: Amorphous with high transparency in solid forms; can be foamed for insulation or cushioning.

Key Strengths: High stiffness, good dimensional stability, low cost, and ease of fabrication.

Applications: Disposable packaging, insulation panels, display cases, and consumer products. High-impact PS variants are used in electronics housings.

key characteristics listed below.

Property | Value / Range |

Tensile Strength | 40-55 MPa |

Flexural Modulus | 2500-3500 MPa |

Elongation | 1-2 % |

Impact | 1-3 kJ/m2 |

Glass Transition Temp | 100 °C |

Continuous Service Temp | 70 |

Density | 1.04-1.06 g/cm3 |

Dielectric | 20-25 kV/mm |

Chemical Resistance | Medium |

Applications & Industry Use Cases: Contact GoodTech MFG for custom PS components.

ABS is an engineering thermoplastic made from three key monomers: acrylonitrile, butadiene, and styrene. Each monomer contributes distinct performance traits: acrylonitrile adds chemical and thermal resistance; butadiene enhances toughness and impact strength; and styrene provides rigidity and excellent surface finish.

Morphology: Amorphous terpolymer consisting of a continuous styrene-acrylonitrile phase and dispersed polybutadiene particles.

Key Strengths: High impact resistance, low creep, dimensional stability, excellent surface finish, and ease of processing for injection molding and thermoforming.

Applications: Automotive interior components, consumer electronics housings, prototyping, and heavy-gauge thermoformed sheets.

key characteristics listed below.

Property | Value / Range |

Tensile Strength | 30-50 MPa |

Flexural Modulus | 2000-2500 MPa |

Elongation | 2-50 % |

Impact | 15-50 kJ/m2 |

Glass Transition Temp | 105 °C |

Continuous Service Temp | 80 |

Density | 1.04-1.06 g/cm3 |

Dielectric | 15-20 kV/mm |

Chemical Resistance | Medium |

Applications & Industry Use Cases: Contact GoodTech MFG for custom ABS components.

PVC is a versatile thermoplastic polymer derived from vinyl chloride monomers. It can be formulated as rigid or flexible by adding plasticizers.

Morphology: Semi-crystalline to amorphous depending on additives, offering rigidity in pipes or flexibility in tubing.

Key Strengths: Chemical and corrosion resistance, fire retardancy, durability, and ease of extrusion and molding.

Applications: Piping, window profiles, electrical insulation, medical tubing, and flooring.

key characteristics listed below.

Property | Value / Range |

Tensile Strength | 40-55 MPa |

Flexural Modulus | 2500-3500 MPa |

Elongation | 10-50 % |

Impact | 5-20 kJ/m2 |

Glass Transition Temp | 75 °C |

Continuous Service Temp | 60 |

Density | 1.3-1.45 g/cm3 |

Dielectric | 15-25 kV/mm |

Chemical Resistance | High |

Applications & Industry Use Cases: Contact GoodTech MFG for custom PVC components.

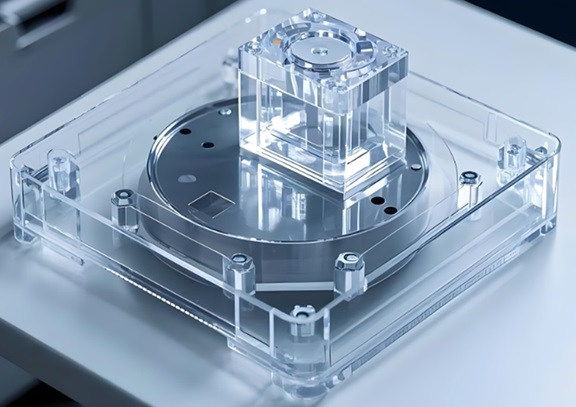

PC is an amorphous engineering thermoplastic synthesized from bisphenol-A and phosgene. Its molecular structure provides exceptional toughness and optical clarity.

Morphology: Amorphous, transparent polymer with high impact strength and dimensional stability.

Key Strengths: High impact resistance, transparency, thermal stability, good electrical insulation, and machinability.

Applications: Safety equipment, lenses, electronic housings, automotive headlamp lenses, and optical discs.

key characteristics listed below.

Property | Value / Range |

Tensile Strength | 55-75 MPa |

Flexural Modulus | 2200-2500 MPa |

Elongation | 100-150 % |

Impact | 55-75 kJ/m2 |

Glass Transition Temp | 147 °C |

Continuous Service Temp | 115 |

Density | 1.20-1.22 g/cm3 |

Dielectric | 15-20 kV/mm |

Chemical Resistance | Medium |

Applications & Industry Use Cases: Contact GoodTech MFG for custom PC components.

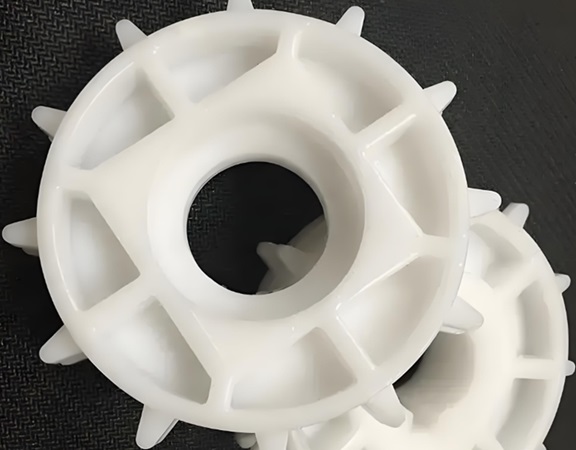

PA6/PA66 is a semi-crystalline polymer made from diamines and dicarboxylic acids. Its molecular structure imparts excellent mechanical strength and wear resistance.

Morphology: Semi-crystalline, leading to high tensile strength and abrasion resistance.

Key Strengths: High mechanical strength, chemical resistance, wear resistance, low friction, and good thermal stability.

Applications: Gears, bearings, automotive components, industrial machinery, and textile fibers.

key characteristics listed below.

Property | Value / Range |

Tensile Strength | 50-90 MPa |

Flexural Modulus | 2000-3000 MPa |

Elongation | 20-300 % |

Impact | 15-40 kJ/m2 |

Glass Transition Temp | 50-60 °C |

Continuous Service Temp | 80-120 |

Density | 1.13-1.15 g/cm3 |

Dielectric | 15-20 kV/mm |

Chemical Resistance | High |

Applications & Industry Use Cases: Contact GoodTech MFG for custom PA6/PA66 components.

PMMA is an amorphous thermoplastic derived from methyl methacrylate monomers. Known for its optical clarity and weather resistance.

Morphology: Amorphous, rigid, and transparent polymer.

Key Strengths: Excellent transparency, UV resistance, dimensional stability, and aesthetic surface finish.

Applications: Displays, lighting, signage, lenses, and protective barriers.

key characteristics listed below.

Property | Value / Range |

Tensile Strength | 50-90 MPa |

Flexural Modulus | 2400-3200 MPa |

Elongation | 2-5 % |

Impact | 2-4 kJ/m2 |

Glass Transition Temp | 105 °C |

Continuous Service Temp | 80 |

Density | 1.18-1.20 g/cm3 |

Dielectric | 15-20 kV/mm |

Chemical Resistance | Medium |

Applications & Industry Use Cases: Contact GoodTech MFG for custom PMMA components.

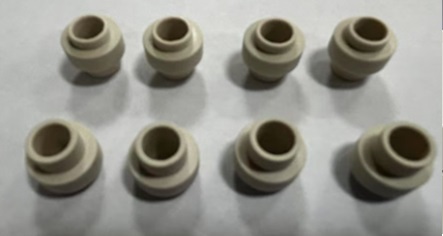

POM is a semi-crystalline thermoplastic polymer synthesized from formaldehyde. Its molecular structure offers high stiffness and low friction.

Morphology: Semi-crystalline with high density and strong molecular packing.

Key Strengths: Dimensional stability, low friction, wear resistance, high tensile strength, and chemical resistance.

Applications: Precision gears, bearings, fasteners, automotive components, and industrial machinery parts.

key characteristics listed below.

Property | Value / Range |

Tensile Strength | 50-70 MPa |

Flexural Modulus | 2500-3000 MPa |

Elongation | 20-30 % |

Impact | 15-25 kJ/m2 |

Glass Transition Temp | -60 °C |

Continuous Service Temp | 100 |

Density | 1.41-1.43 g/cm3 |

Dielectric | 15-20 kV/mm |

Chemical Resistance | High |

Applications & Industry Use Cases: Contact GoodTech MFG for custom POM components.

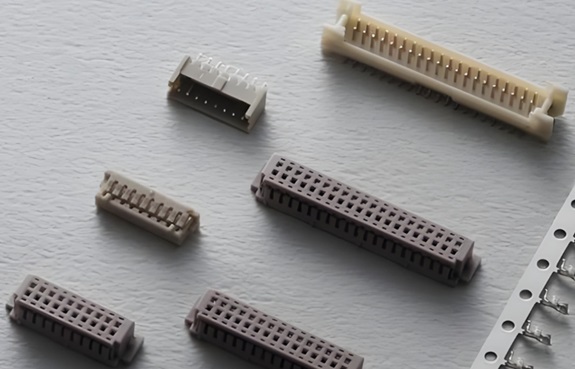

PBT is a semi-crystalline engineering polyester produced from butanediol and terephthalic acid.

Morphology: Semi-crystalline structure allows thermal and dimensional stability with low moisture absorption.

Key Strengths: Chemical resistance, dimensional stability, electrical insulation, low creep, and fatigue resistance.

Applications: Electrical connectors, automotive components, consumer electronics, and mechanical parts.

key characteristics listed below.

Property | Value / Range |

Tensile Strength | 50-80 MPa |

Flexural Modulus | 2400-2800 MPa |

Elongation | 20-50 % |

Impact | 15-25 kJ/m2 |

Glass Transition Temp | 22-25 °C |

Continuous Service Temp | 120 |

Density | 1.31-1.33 g/cm3 |

Dielectric | 15-20 kV/mm |

Chemical Resistance | High |

Applications & Industry Use Cases: Contact GoodTech MFG for custom PBT components.

PET is a semi-crystalline thermoplastic polyester formed from ethylene glycol and terephthalic acid.

Morphology: Semi-crystalline with excellent strength and barrier properties.

Key Strengths: High tensile strength, chemical resistance, dimensional stability, and clarity in amorphous forms.

Applications: Bottles, films, packaging, reinforced composites, and mechanical parts.

key characteristics listed below.

Property | Value / Range |

Tensile Strength | 50-80 MPa |

Flexural Modulus | 2500-3000 MPa |

Elongation | 20-50 % |

Impact | 15-30 kJ/m2 |

Glass Transition Temp | 75 °C |

Continuous Service Temp | 120 |

Density | 1.38-1.40 g/cm3 |

Dielectric | 15-20 kV/mm |

Chemical Resistance | High |

Applications & Industry Use Cases: Contact GoodTech MFG for custom PET components.

ABS+PC blends combine ABS toughness with PC’s high impact strength and heat resistance.

Morphology: Amorphous, combining a rubber-toughened ABS phase with a rigid PC phase.

Key Strengths: Improved impact strength, thermal stability, dimensional accuracy, and surface finish.

Applications: Automotive interior panels, electronic housings, and safety equipment.

key characteristics listed below.

Property | Value / Range |

Tensile Strength | 55-75 MPa |

Flexural Modulus | 2200-2600 MPa |

Elongation | 50-100 % |

Impact | 50-70 kJ/m2 |

Glass Transition Temp | 110 °C |

Continuous Service Temp | 90 |

Density | 1.10-1.20 g/cm3 |

Dielectric | 15-20 kV/mm |

Chemical Resistance | Medium |

Applications & Industry Use Cases: Contact GoodTech MFG for custom ABS+PC components.

PPS is a high-performance semi-crystalline polymer with a rigid aromatic backbone and sulfur linkages.

Morphology: Semi-crystalline with high thermal and chemical stability.

Key Strengths: Chemical resistance, high heat resistance, dimensional stability, and flame retardancy.

Applications: Automotive under-the-hood components, electrical connectors, and industrial machinery.

key characteristics listed below.

Property | Value / Range |

Tensile Strength | 70-90 MPa |

Flexural Modulus | 4000-4500 MPa |

Elongation | 2-5 % |

Impact | 5-15 kJ/m2 |

Glass Transition Temp | 90 °C |

Continuous Service Temp | 200 |

Density | 1.35-1.38 g/cm3 |

Dielectric | 15-25 kV/mm |

Chemical Resistance | High |

Applications & Industry Use Cases: Contact GoodTech MFG for custom PPS components.

PEEK is a semi-crystalline high-performance polymer with aromatic ketone and ether linkages.

Morphology: Semi-crystalline, retaining mechanical properties at elevated temperatures.

Key Strengths: Exceptional thermal stability, chemical resistance, mechanical strength, and wear resistance.

Applications: Aerospace components, medical implants, high-performance bearings, and industrial parts.

key characteristics listed below.

Property | Value / Range |

Tensile Strength | 90-120 MPa |

Flexural Modulus | 3600-4000 MPa |

Elongation | 20-50 % |

Impact | 20-40 kJ/m2 |

Glass Transition Temp | 143 °C |

Continuous Service Temp | 250 |

Density | 1.30-1.32 g/cm3 |

Dielectric | 15-25 kV/mm |

Chemical Resistance | High |

Applications & Industry Use Cases: Contact GoodTech MFG for custom PEEK components.

TPE is a block copolymer combining elastomeric and thermoplastic properties, offering flexibility and processability.

Morphology: Phase-separated structure with soft rubbery domains in a hard thermoplastic matrix.

Key Strengths: Elasticity, chemical resistance, processable by injection molding, and low-temperature flexibility.

Applications: Seals, gaskets, grips, tubing, and flexible automotive parts.

key characteristics listed below.

Property | Value / Range |

Tensile Strength | 15-50 MPa |

Flexural Modulus | 5-50 MPa |

Elongation | 200-700 % |

Impact | 5-25 kJ/m2 |

Glass Transition Temp | -60 to -50 °C |

Continuous Service Temp | 90 |

Density | 0.90-1.20 g/cm3 |

Dielectric | 15-25 kV/mm |

Chemical Resistance | Medium |

Applications & Industry Use Cases: Contact GoodTech MFG for custom TPE components.

TPU is an elastomeric thermoplastic with segmented polymer chains of hard and soft blocks.

Morphology: Phase-separated with hard domains providing mechanical strength and soft domains providing flexibility.

Key Strengths: Abrasion resistance, elasticity, chemical resistance, and transparency in some grades.

Applications: Footwear, protective films, hoses, flexible tubing, and medical devices.

key characteristics listed below.

Property | Value / Range |

Tensile Strength | 25-80 MPa |

Flexural Modulus | 10-100 MPa |

Elongation | 300-600 % |

Impact | 5-30 kJ/m2 |

Glass Transition Temp | -50 °C |

Continuous Service Temp | 80 |

Density | 1.10-1.25 g/cm3 |

Dielectric | 15-25 kV/mm |

Chemical Resistance | Medium |

Applications & Industry Use Cases: Contact GoodTech MFG for custom TPU components.

PHENOLIC RESIN is a thermosetting polymer formed from phenol and formaldehyde.

Morphology: Highly crosslinked, rigid, and amorphous.

Key Strengths: Heat resistance, dimensional stability, chemical resistance, and electrical insulation.

Applications: Laminates, molded electrical components, circuit boards, and brake components.

key characteristics listed below.

Property | Value / Range |

Tensile Strength | 40-70 MPa |

Flexural Modulus | 3000-4000 MPa |

Elongation | 1-3 % |

Impact | 5-10 kJ/m2 |

Glass Transition Temp | 150 °C |

Continuous Service Temp | 120 |

Density | 1.30-1.35 g/cm3 |

Dielectric | 20-30 kV/mm |

Chemical Resistance | High |

Applications & Industry Use Cases: Contact GoodTech MFG for custom PHENOLIC RESIN components.

EPOXY RESIN is a thermosetting polymer with reactive epoxide groups that crosslink with hardeners.

Morphology: Crosslinked network providing rigidity and stability.

Key Strengths: High adhesion, chemical resistance, dimensional stability, and electrical insulation.

Applications: Coatings, adhesives, composite materials, and electrical components.

key characteristics listed below.

Property | Value / Range |

Tensile Strength | 30-70 MPa |

Flexural Modulus | 2000-4000 MPa |

Elongation | 1-5 % |

Impact | 5-15 kJ/m2 |

Glass Transition Temp | 60-120 °C |

Continuous Service Temp | 80-150 |

Density | 1.15-1.30 g/cm3 |

Dielectric | 15-25 kV/mm |

Chemical Resistance | High |

Applications & Industry Use Cases: Contact GoodTech MFG for custom EPOXY RESIN components.

POLYIMIDE is a high-performance polymer with aromatic imide linkages, offering extreme thermal and chemical stability.

Morphology: Semi-crystalline to amorphous depending on processing; retains integrity at high temperatures.

Key Strengths: Thermal stability, mechanical strength, chemical resistance, and electrical insulation.

Applications: Flexible printed circuits, aerospace components, insulating films, and high-temperature industrial parts.

key characteristics listed below.

Property | Value / Range |

Tensile Strength | 90-110 MPa |

Flexural Modulus | 3000-4000 MPa |

Elongation | 10-20 % |

Impact | 10-20 kJ/m2 |

Glass Transition Temp | 300 °C |

Continuous Service Temp | 250 |

Density | 1.40-1.45 g/cm3 |

Dielectric | 20-30 kV/mm |

Chemical Resistance | High |

Applications & Industry Use Cases: Contact GoodTech MFG for custom POLYIMIDE components.