GoodTech MFG Group Limited

Handson Zingying Plastic Metal Ltd

Handson Zingying Plastic Metal Ltd

Views: 42 Author: Site Editor Publish Time: 2021-12-28 Origin: Site

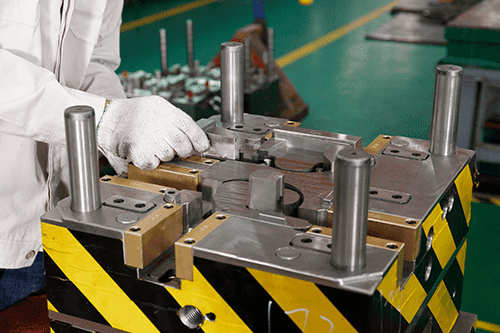

There are many areas in life that need to use custom plastic injection molds, And many of the items that everyone produces also require molds to be produced. For example, computers, keyboards or car steering wheels all require molds. In addition to these relatively large items, molds are required, as well as some small things. It also requires molds to produce, but precision plastic injection molds are needed in the production of molds, such as mobile phone molds and the back shell of remote control, etc. These all require very complex molds to be produced. Yes, the requirements will be higher, so what should we pay attention to for high-precision molds? Take a look.

In life, precision plastic injection molds have high requirements for assembly size, so when producing high-precision molds, you must choose a good mold manufacturing factory. It not only needs to meet the requirements in terms of size, but also needs to meet standards in terms of style. of. Compared with ordinary molds, it has extremely high precision requirements. Therefore, when making high-precision molds, we must pay attention to the extremely high requirements for instruments. Therefore, we must understand the needs of customers when designing high-precision molds. Only by meeting customer needs can we produce high-precision molds of higher quality.

Nowadays, in many industrial productions, there are indeed some parts, and their proportions are extremely precise, so mold production is also needed during production. High-precision molds should also pay attention to the need to pay attention when using them. The electrode cannot be deflected. If the electrode is deflected, it will have a great impact on the accuracy of the mold after use, and it will also make the products produced by the precision mold. There is a quality problem. When choosing a mold manufacturer, it is necessary to choose a manufacturer with the strength in this area to be able to work efficiently. In addition, it can also produce better high-precision molds.

How can we make precision plastic injection molds?

If you want to make high-precision molds, you must choose a good plastic mold tooling company high-precision molds. In addition to choosing a regular manufacturer when making high-precision molds, you must also understand that the factory is producing When using high-precision molds, will the same electrode material be used for a long time? If the same electrode material is used for a long time, it will also cause problems in the high-precision molds produced, avoiding the use of the same type for a long time to improve work efficiency Electrode material. In addition, when making high-precision molds, you must choose a machine with a relatively high precision, and you cannot produce it by artificial methods.

Because when some plastic injection mold manufacturers produce high-precision molds, in order to improve efficiency, they will manually install or adjust the motor. This will affect the production of high-precision molds. The reason why it is called high-precision mold is that compared with ordinary molds, this kind of mold has extremely high requirements and high accuracy. Only by meeting these ultra-high requirements can high-precision molds be able to meet the standards and produce more For high-quality products, especially those with relatively small parts, if you don't know how to choose, you can also choose Goodtech to meet customer needs and make high-precision molds.