GoodTech MFG Group Limited

Handson Zingying Plastic Metal Ltd

Handson Zingying Plastic Metal Ltd

Views: 48 Author: Site Editor Publish Time: 2022-01-18 Origin: Site

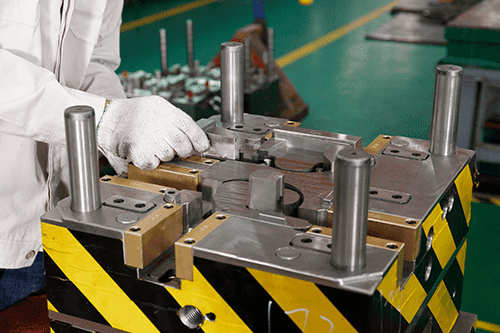

Custom plastic injection molds are workers who are used to mold items, such tools are made of various parts, and different molds are made of different parts.

It mainly realizes the processing of the shape of the article by changing the physical state of the formed material. In the process of cutting, forming stamping, die forging, cold heading, extrusion, powder metallurgy pressing, pressure casting, as well as the compression molding or injection molding of engineering plastics, rubber, ceramics and other products, it is used under the action of external force. A tool for making blanks into parts of a specific shape and size.

Mold maintenance needs to be repaired by qualified mold maintenance workers who have undergone professional training. During maintenance, you must know the technical standards of the mold. For example, the die-casting mold is a kind of activity that will cause special precision machinery. Superb technology, fine style, but also a serious and responsible spirit. Therefore, let's take a look at the precautions for good injection mold maintenance.

1. It is all about cleaning the metal small and fouling around the mold, showing the true color of the mold.

2. Refer to the last die-casting product sent together with the mold for repair, and carefully check the problems existing in the mold. Whether there is any strain, mold sticking, crushing, falling meat, whether the small core is bent or broken, whether the movable core is inserted and positioned inaccurately, whether the push rod is broken or the length of the push rod changes, whether the fastening bolts are loose Wait. Determine repair or replacement based on damage

3. Partial welding repairs can be performed for cavity collapse, cracks, and falling blocks that cause slight strains of castings. Welding repairs should be operated in strict accordance with the welding repair process, otherwise a lot of mold life will be lost. The above failures are more serious for smaller molded parts or the mold is damaged.

4. If the molding surface of the larger molding part is seriously collapsed, cracked, or dropped, it can be repaired by local welding. The welding repair and repair should be operated strictly according to the welding repair process, otherwise a lot of mold life will be lost. The above failures are more serious for smaller molded parts or the mold is damaged.

5. The sliding parts such as core pulling mechanism and guide device should be thoroughly cleaned, carefully checked and maintained. Assemble after relubrication with high temperature grease.

6. If there is hydraulic core pulling, the hydraulic part and the mold will be repaired at the same time. The maintenance of the hydraulic department pays special attention to cleaning to prevent contamination, otherwise it will contaminate the entire hydraulic system of the die-casting machine.

7. When the mold fails or is damaged in the production project, the repair plan should be determined according to the specific situation. If necessary, perform comprehensive repairs as described above.

8. For the mold that has been repaired and maintained, the molding surface, parting surface, and installation surface are treated with anti-rust treatment, and the mold is closed and fixed, and placed on the backing plate according to the installation direction of the injection mold on the machine. The mold attachment is placed with the mold.